Behind every neatly arranged shelf in a retail store lies a surprisingly time-consuming task: managing price labels. For multi-location stores or retailers with frequent price changes, this process isn’t just tedious—it’s a significant drain on labor and accuracy. For decision-makers grappling with rising labor costs and the need for operational agility, electronic shelf labels offer a strategic path forward—bridging physical stores with real-time digital control.

The Hidden Cost of Manual Price Labeling

Traditional paper labeling might seem affordable at first glance, but the long-term labor burden and inefficiencies can quietly drain profit margins. Let's break down a typical manual labeling scenario in a grocery store:

Store Size: 8,000 SKUs

Average Price Changes Per Month: 2 times

Manual Update Time Per Label: 1.5 minutes

Hourly Staff Cost: $15/hour

That’s 400 hours/month, or $6,000 in labor cost—just for changing price tags. Multiply that across chains or seasonal pricing cycles, and the numbers become unsustainable.

Using a labor burden calculator, it becomes clear that ESLs can offer a full return on investment in less than 18 months for mid-sized stores—especially when accounting for reduced label printing costs and human error losses.

Why More Retailers Are Investing in Electronic Labels

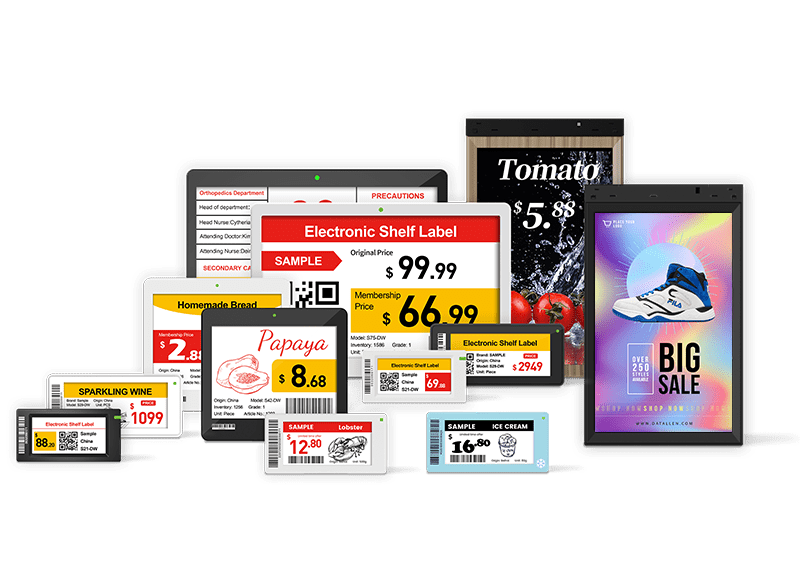

Modern electronic labels go far beyond static displays. Here’s why they’re being adopted across fresh food supermarkets, convenience stores, pharmacies, and electronics retailers:

Real-Time Price Syncing: Reflect dynamic pricing instantly across thousands of labels.

Sustainability: Reduce label waste and carbon footprint.

Customer Experience: Cleaner visuals, clear promotions, and faster in-store navigation.

Inventory Accuracy: Integrate with back-end systems for smarter stock rotation and replenishment alerts.

These benefits translate to hard metrics like increased retail store efficiency, improved employee productivity, and a stronger customer perception of innovation.

Inside the ESL System: How It Works with Datallen

To truly understand the impact of ESLs, let’s walk through the actual operation process using Datallen, a trusted electronic labeling solution provider serving global retailers.

1. Simple Gateway Setup

Retailers begin by installing a base station, which is a lightweight device that connects to both the power supply and local network via Ethernet. Each station can control up to 4,000 ESL units wirelessly, providing excellent scalability for large store formats or multiple zones.

2. Label ID Binding

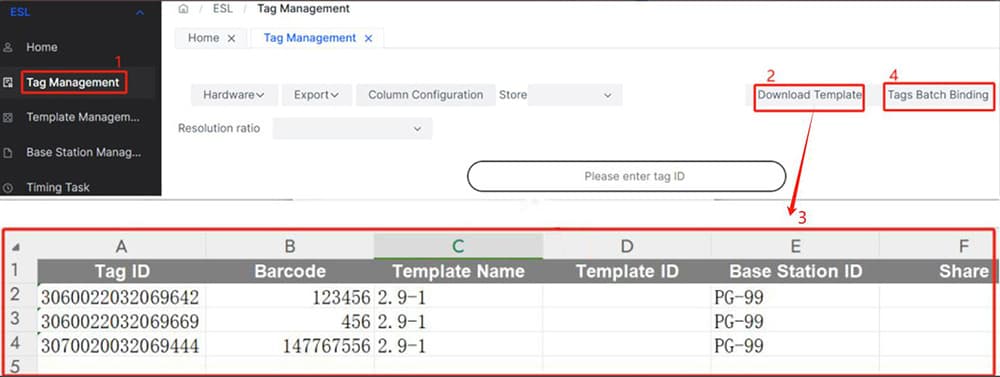

Before shipment, each ESL is assigned a unique ID and pre-uploaded to the retailer’s system account. Retailers can then easily locate and assign specific labels via ID search without complicated manual mapping.

3. Flexible Installation Options

Whether it’s metal shelves, glass coolers, or produce racks, Datallen offers a wide variety of mounting ESL accessories, including:

ESL Rails

Clips and Telescopic Pole Stands

Tabletop Stands & Wall Mount Kits

Waterproof Cases

Double-sided Hanging Displays

Ice Stick Mounts for Freezers

These options ensure ESLs can be deployed quickly—even by a single staff member.

4. Fast Content Setup

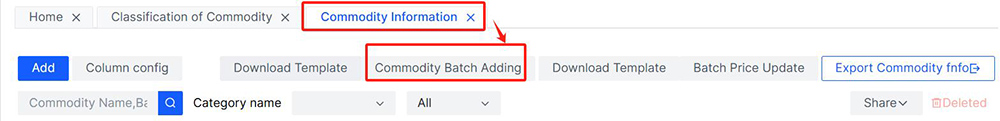

Datallen’s ESL system supports intuitive product management:

Upload Commodities: Add SKUs individually or use batch upload features.

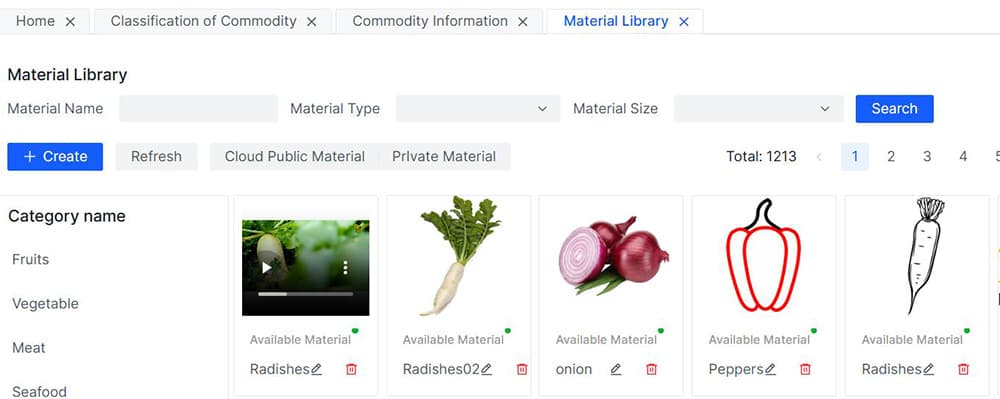

Select Content: Choose from thousands of built-in commodity images, videos, or upload your own media.

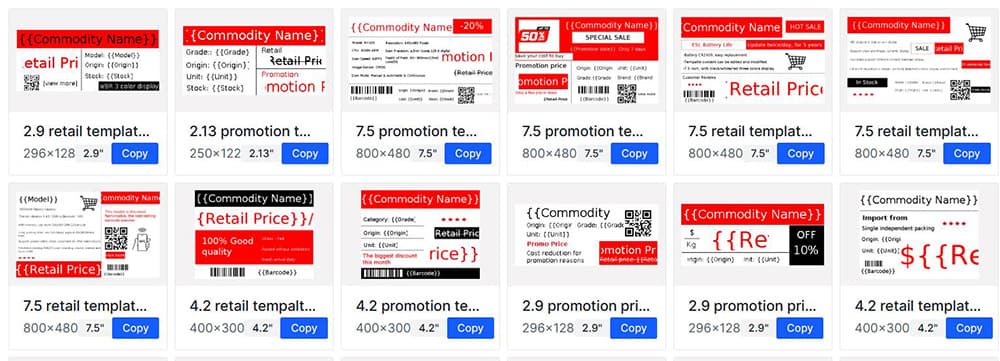

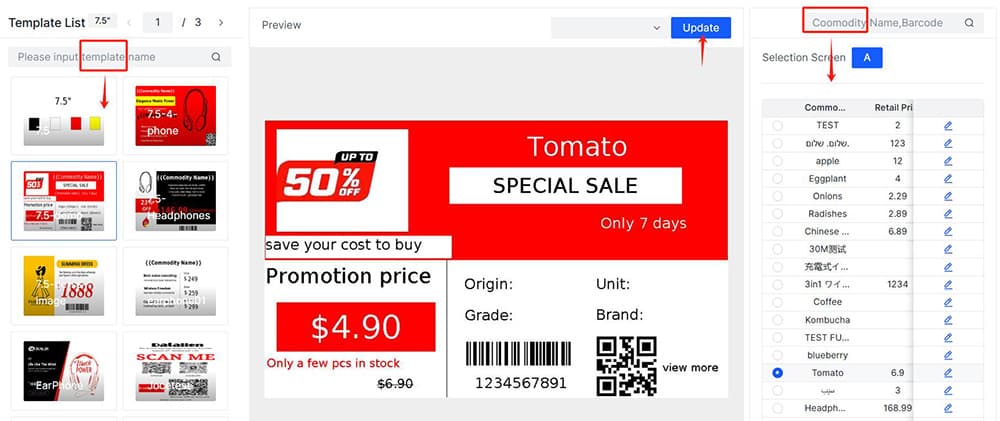

Design or Apply Templates: Built-in industry-specific templates and a visual drag-and-drop editor allow for quick layout customization.

Bind and Refresh: Match a commodity with a tag ID and a template—then click "Update" for real-time display.

Supports mass binding, ideal for large-format stores and chain operations.

This process is particularly valuable for stores managing large inventories—cutting down update time from hours to mere minutes.

With drag-and-drop templates and batch import options, store managers can easily deploy content without needing technical skills. Once deployed, templates or product pricing details can be updated remotely anytime, with just one click to trigger real-time synchronization across all electronic labels.

What Do Electronic Labels Cost?

One of the most frequently asked questions from store owners is: “What’s the cost of electronic shelf labels?”

ESL pricing varies by size, but average investments range from $5–$10 per label, depending on the display technology and size (e.g., 2.13", 2.9", 4.2", or 7.5" displays). However, when compared to the recurring label printing cost, plus wages associated with manual updates, ESLs pay for themselves quickly.

According to internal customer case studies, retailers using Datallen ESLs experienced:

60–90% reduction in price update time

Up to 20% drop in human pricing errors

Increased in-store promotion responsiveness

Lower long-term operational costs

Seamless System Integration: Enhancing Accuracy and Efficiency Across Channels

Modern ESL systems are no longer standalone tools — they are increasingly designed to integrate seamlessly with existing POS, ERP, and warehouse management systems (WMS). For retailers, this means synchronized pricing across all sales channels and streamlined inventory updates. For example, when a product price is changed in the POS or ERP system, the update is automatically reflected on all associated electronic labels in real time, eliminating manual relabeling and reducing pricing errors.

Datallen’s ESL solution supports API integration, allowing retailers and solution providers to connect the ESL platform with in-house or third-party systems. This ensures real-time synchronization of product pricing, inventory levels, and promotions. Such integration not only improves operational efficiency but also minimizes mismatches between digital displays and backend systems.

Who Benefits Most from ESLs?

These solutions are ideal for:

Grocery Chains & Supermarkets: Managing fast-turning items like produce, dairy, seafood.

Convenience Stores: Updating regional promotions in real-time.

Pharmacies: Regulating drug pricing compliance.

Consumer Electronics: Quickly adjusting prices during high-volume events like Black Friday.

Retail Integrators & Solution Providers: Offering digital shelf conversion as a service.

Whether you're a store owner looking to scale smarter or a retail integrator seeking reliable solutions for your clients, electronic labels represent a measurable way to add value.

Electronic Label Is the Future

The future of retail is data-driven, agile, and sustainable. Electronic labels aren’t just digital upgrades—they're enablers of faster execution, cleaner stores, and higher customer trust.

For retailers, the case is clear: reduce retail labor costs, eliminate label printing costs, and unlock centralized pricing power with Datallen.

Discover how Datallen can streamline your pricing operations and maximize retail efficiency at www.datallen.com

For more insights, check out:

1. Smart Shelf Technology-The Future of Inventory, Efficiency, and Green Retailing

2. High Fashion Furniture Store Display Ideas Powered by Electronic Paper Display

3. How Much Does It Cost to Open a Smart Store with e Price Tags?

4. Different Types of Product Labels: A Retailer’s Guide to Choosing the Right Solution

5. Creative Digital Price Tag Ideas for Modern Supermarket Shelving