Effective inventory management is the invisible thread that weaves together customer satisfaction, operational efficiency, and financial health. For grocers, wholesalers, e-commerce sellers, and brick-and-mortar stores alike, balancing stock levels—avoiding shortages that disappoint customers and overstock that ties up capital—has never been more critical. Let’s explore how businesses can tailor strategies to their unique needs, leveraging technology and proven methods to thrive in today’s dynamic market.

Why Inventory Management Matters for Your Business

At its core, inventory management is about harmony: matching what’s in stock with what customers want, when they want it. For a grocery store, it means fresh produce on shelves without spoilage; for a warehouse, it ensures rapid order fulfillment without wasted space. Poor inventory control leads to missed sales, inflated storage costs, and strained supplier relationships. Conversely, a well-tuned system boosts cash flow, enhances customer loyalty, and frees teams to focus on growth.

Core Principles of Inventory Management

Inventory management isn’t one-size-fits-all. Perpetual systems, used by many modern retailers, track real-time stock levels through point-of-sale (POS) integrations, while periodic systems rely on occasional audits—better suited for smaller businesses. Metrics like inventory turnover rate (how quickly stock sells) and carrying costs (storage, insurance, depreciation) guide decision-making. Tools like ABC analysis help classify items: high-value “A” products (e.g., electronics) need tight control, while low-margin “C” items (e.g., grocery staples) thrive with automated reordering.

Industry-Specific Inventory Strategies

A. Grocery Inventory Management: Balancing Freshness and Efficiency

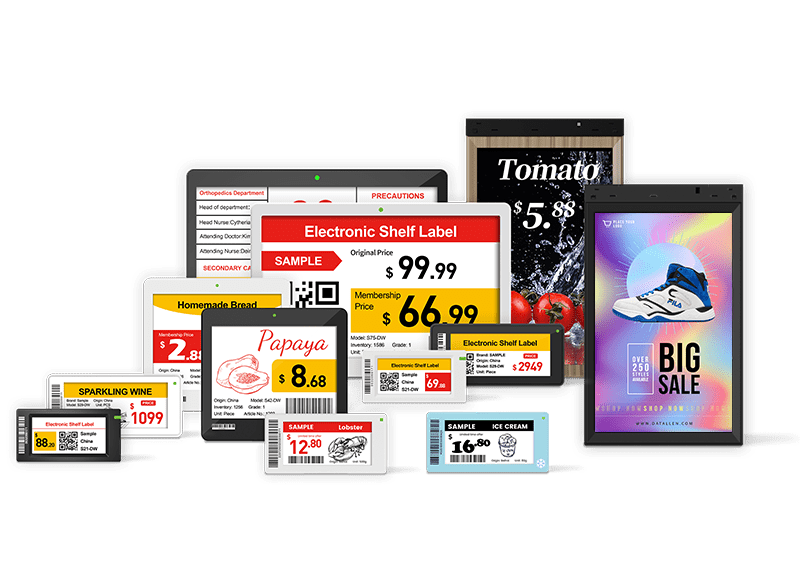

Grocery inventory management is, in many ways, a precise dance with time. Shelf-life tracking is non-negotiable—implementing FIFO (First-In, First-Out) ensures older stock moves first, reducing waste. Smart solutions like electronic shelf labels (ESLs) update prices and expiration dates in real-time, empowering staff to restock efficiently. Seasonal demand shifts, from holiday baking supplies to summer grilling essentials, require agile forecasting to avoid overstocking or running out of stock.

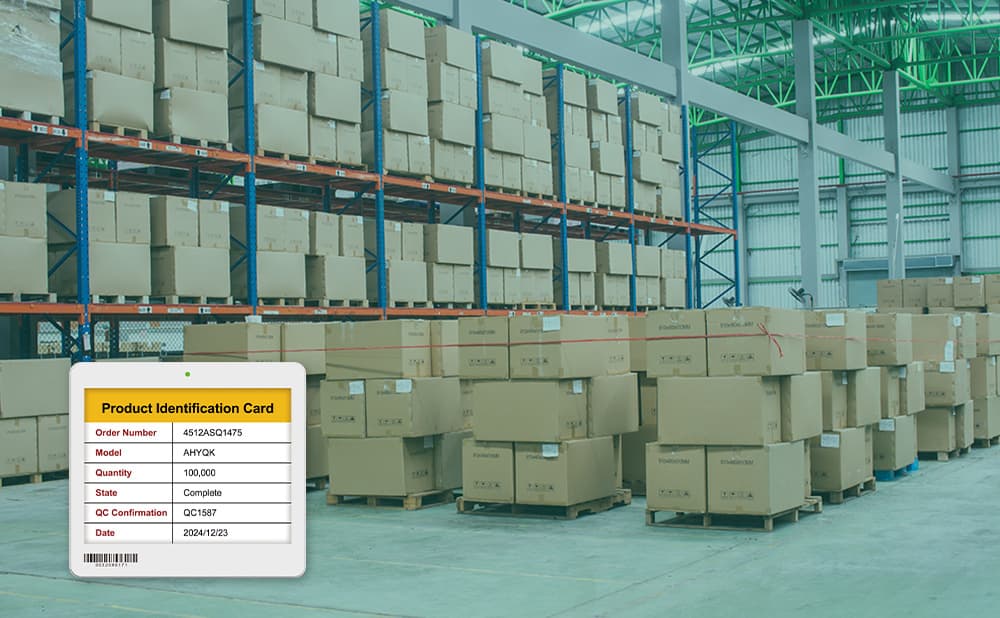

B. Warehouse Optimization: Maximizing Space and Speed

Warehouses thrive on efficiency. Vertical storage—think adjustable racks and mezzanine levels—turns unused ceiling space into valuable real estate. Cross-docking, where goods move directly from incoming to outgoing trucks, cuts storage time and labor costs. Warehouse Management Systems (WMS) act as nerve centers, optimizing pick paths and flagging low-stock items before delays occur.

C. Retail Inventory Control: Enhancing In-Store Experience

In physical stores, shelf layout is everything. High-turnover items like snacks or beauty basics deserve prime real estate while slower-moving goods can occupy higher shelves. Inventory shrinkage—from theft or miscounts—eats into profits, making tools like RFID tags and staff training vital. POS systems that sync across locations ensure customers know if an item is available at a nearby store, blending convenience with accuracy.

D. E-Commerce Inventory: Navigating Multi-Channel Complexity

Online sellers face a unique challenge: syncing inventory across platforms (Amazon, Shopify, their site) while managing 3PL partnerships. Dropshipping requires seamless communication with suppliers, while centralized warehousing may struggle with shipping speeds. Automated order routing ensures the nearest warehouse fulfills each order, cutting delivery times and costs.

Technology-Driven Inventory Solutions

Modern inventory management hinges on technology. AI-driven forecasting analyzes historical data, seasonality, and even social trends to predict demand with stunning accuracy, reducing guesswork. IoT-enabled sensors in warehouses monitor stock levels and environmental conditions (e.g., temperature for pharmaceuticals), triggering alerts before issues arise. For grocers, ESLs aren’t just for prices—they can display real-time stock availability, helping shoppers and staff alike navigate shelves with confidence.

Enterprise solutions like SAP or Zoho Inventory offer end-to-end visibility, while smaller businesses benefit from user-friendly platforms like QuickBooks Commerce. The common thread? Integration—ensuring data flows smoothly from the warehouse floor to the customer’s cart.

Space Optimization Techniques for Warehouses

Efficient storage is a science. Narrowing aisle widths (while ensuring safety for forklifts) and installing adjustable racks can boost warehouse capacity by 30%. Grouping items by size, sales velocity, or storage needs (e.g., refrigerated goods in groceries) streamlines picking and restocking. Regular cycle counts—auditing a subset of inventory frequently—catch discrepancies early, preventing costly year-end surprises.

Overcoming Inventory Challenges

- Overstocking/Understocking: Often due to inaccurate forecasts or inflexible supply chains. Cure: Partner with suppliers for vendor-managed inventory (VMI) and use AI to adjust orders dynamically.

- Discrepancies: Manual errors or system lags cause mismatches. Solution: Barcode scanning and real-time WMS updates, reducing human error by up to 95%.

- Inefficiency: Stagnant processes drain time and money. Remedy: Automate replenishment triggers and invest in staff training for new technologies.

Cost Management Strategies

Carrying costs can eat 20-30% of an item’s value annually. Learn strategies like just-in-time (JIT) delivery (receiving goods as needed) and consignment models (paying suppliers after sales) free up capital. Case in point: A mid-sized warehouse using WMS and AI reduced carrying costs by 25% in one year, reinvesting savings into expansion.

Future of Inventory Management

Innovation marches on. Predictive analytics will grow smarter, anticipating demand surges from viral trends or weather events. Sustainability will take center stage, with optimized logistics cutting carbon footprints and waste. For grocers, smart shelves that track item movement will enable real-time stock adjustments, turning every aisle into a data-driven hub.

Real-World Success Stories

A regional grocery chain adopted ESLs and FIFO tracking, cutting spoilage by 18% and freeing staff to engage customers instead of manual inventory checks. A wholesale distributor used a WMS to reorganize warehouse racks, increasing storage capacity by 40% without expanding facilities. These stories share a truth: Tailored strategies, paired with the right tools, drive tangible results.

Building a Resilient Inventory Strategy

No two businesses are the same. Whether you run a corner grocery, a sprawling warehouse, or an e-commerce empire, the key is flexibility: adapting strategies to your industry, scale, and customer needs. Leverage data, embrace technology where it adds value, and remember—inventory management isn’t just about numbers. It’s about ensuring every product finds its way to the right person at the right time, turning operational excellence into lasting relationships.

For more insights, check out:

7 Key Considerations for Implementing Digital Shelf Tags in Warehouses

POP Materials vs. Smart POS Systems: Transforming Retail Marketing